Quantum Annealing in a Proof of Technology

Pfizer Freiburg explores new methods in production planning

Quantum computing is hailed as a revolutionary future technology, but for many companies, it's still a distant dream. At Pfizer's production plant, quantum annealing technology was used for the first time to optimize production planning and compared with traditional optimization methods. This flagship project was initiated and led by the Pfizer Healthcare Hub Freiburg, in collaboration with QuantumBasel and D-Wave. Recently, the proof of technology was achieved, and the results are promising.

“Science will win and Digital will help us to win faster*”

Since the installation of the first IBM Quantum Computer in Germany in June 2021, a vibrant ecosystem has emerged in Baden-Württemberg, enabling the state to enhance its leadership in quantum computing. In October 2023, we spoke with Thomas Kleine, who was then the County Digital Lead at Pfizer, about the potential of quantum technology for the healthcare industry:

"Quantum computing perfectly aligns with our core principles 'Science will win' and 'Time is life.' We aim to boldly forge ahead and explore new possibilities. Our mission is to improve the lives of patients worldwide. To achieve this, we must always stay at the cutting edge of innovation."

Tomorrow's game changer: How the use of quantum computing can revolutionize the healthcare industry

The Pfizer Healthcare Hub brings cutting-edge technologies to Pfizer

The Pfizer Healthcare Hub is one of Pfizer's innovation drivers. In Freiburg, Peter Neske, Pembe Gül Bilir, and Oana Elena Stürz, along with innovators from various departments, match specific use cases from the Pfizer ecosystem with innovative technologies from external partners.

"Since the establishment of the Pfizer Healthcare Hub Freiburg in 2018, we have been sharing our expertise and support with the innovation ecosystem, engaging in dialogue with startups and companies, and maintaining ongoing communication with accelerators and economic promoters," says Peter Neske, Innovation Lead of the Pfizer Healthcare Hub Freiburg.

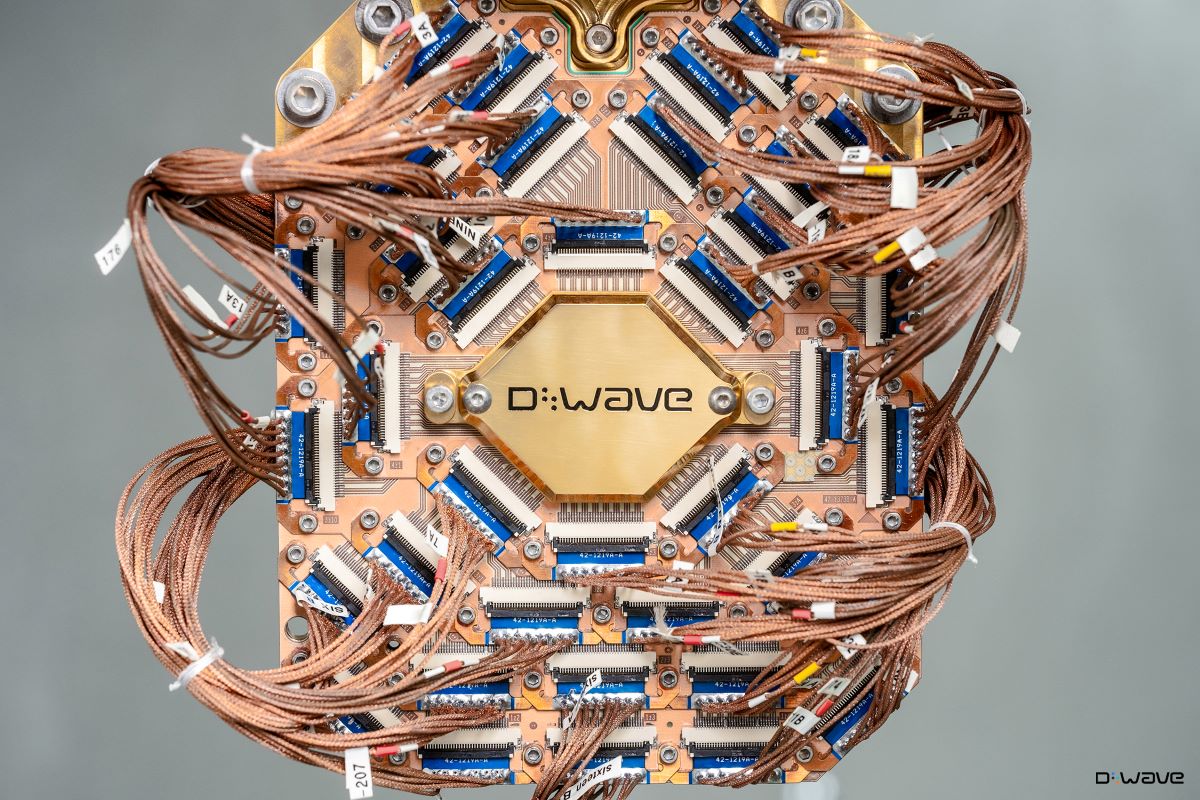

Neske matched Pfizer's commitment to innovation with a challenge in materials management. He expanded the team to include two experienced players from the innovation ecosystem: QuantumBasel, the competence center for quantum technology in the Basel region, which acts as a strategic partner supporting companies in the application of quantum technologies, and D-Wave, QuantumBasel's technology partner, which offers quantum annealing technology.

"We are committed to bridging the gap between quantum technology and real-world industrial applications. By providing quantum computers for specific use cases, we help companies maximize their innovation and efficiency potential," said Damir Bogdan, CEO of QuantumBasel.

The Quantum Annealing Approach to Process Optimization

"How can we optimize production planning at the Freiburg plant and thereby make processes more efficient?"

This central question was at the heart of the recently completed Proof of Technology. The highly complex production planning always offers potential for optimization due to the rapid development of computing power. An ideal application field for quantum technology:

"Quantum computing uses quantum effects to accelerate calculations, this offers a way to quickly identify solutions in a fraction of the time needed by a classical solver," says Murray Thom, Vice President of Quantum Technology Evangelism at D-Wave. "At the Freiburg production plant, we achieved significant savings as a result."

Proof of Technology: How Does the Quantum Annealing Method Perform in Comparison?

Under the leadership of project manager Pembe Gül Bilir and in collaboration with D-Wave and QuantumBasel, the Pfizer team developed the optimized method using quantum annealing.

"Our goal was to evaluate the quantum annealing technology in a real-world application of production planning. We wanted to not only assess the method in isolation but also test and compare alternatives. We focused particularly on which approach offers the maximum benefit for production at acceptable costs," says David Rüde, Site Transformation Lead at Pfizer.

The High Performance Computing team at the Global Center for Digital Innovation in Thessaloniki developed the classical mathematical optimization method. Both optimization methods were compared to the baseline situation based on criteria such as computation time, planning time, completion, and production capacity.

The quantum annealing method delivers an optimized production plan in a comparatively short time

As expected, both methods improved the initial situation, but the quantum-optimized method yielded the best results. The algorithm produced an optimized production plan in a short amount of time, significantly reducing the production cycle while ensuring timely product delivery.

"Quantum annealing can offer significant advantages over purely classical methods, especially when processing larger and more complex datasets. With this use case, Pfizer is taking a pioneering role," said Gavin Kennedy, Global Head of Professional Services.

It is also expected that the quantum-optimized method will outperform classical methods even more clearly with larger and more complex datasets.

"In this proof of technology, we were able to generate meaningful results and important insights into the use of quantum technologies within a few months with an interdisciplinary, global team. The project shows that it is worthwhile to explore the potential applications of future technologies such as quantum computing early on. By using such innovative technologies, we can improve and accelerate the supply of vital medications to our patients. At the same time, a maximum business impact can be achieved, further strengthening our competitiveness," said Pembe Gül Bilir.

... and what's next?

For the production planning use case, the next step is to further develop both the classical and quantum annealing methods and test them with larger and more complex datasets."

Additionally, the D-Wave team recently presented the quantum annealing method to interested Pfizer departments.

Pioneering the future of technology

Quantum technology, once a distant prospect on the innovation horizon, is now becoming tangible. With the successful proof of technology, Pfizer has taken the first step with a future technology that holds potential not only for optimizing production planning but also for many other applications within Pfizer, the healthcare industry, and all manufacturing companies.

*“Science will win and Digital will help us to win faster”, said Mikael Dolsten, Globaler Leiter Pfizer Research & Development.